The Role of Augmented Reality in Training and Maintenance of Electrical Equipment

laser book, silverexch, 11xplay reddy login:The Role of Augmented Reality in Training and Maintenance of Electrical Equipment

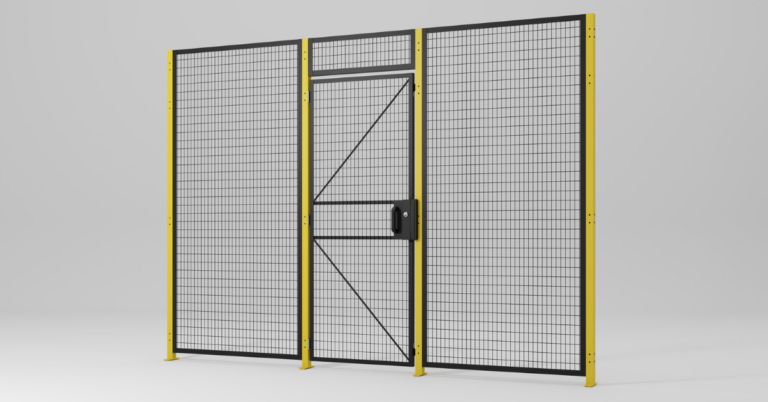

When it comes to maintaining and operating electrical equipment, safety and efficiency are top priorities. Any misstep could result in downtime, costly repairs, or even dangerous situations for workers. That’s where augmented reality (AR) comes in – a cutting-edge technology that has been revolutionizing the way we train and maintain electrical equipment.

In this article, we will delve into the various ways in which AR is changing the game for training and maintenance in the electrical industry. From real-time troubleshooting to interactive training simulations, AR is proving to be a game-changer in this field.

Real-Time Troubleshooting

One of the most significant benefits of AR in the maintenance of electrical equipment is real-time troubleshooting. With AR-enabled devices such as smart glasses or tablets, technicians can overlay digital information onto physical equipment, providing them with instant access to manuals, schematics, and other relevant data.

This means that when an issue arises, technicians can quickly identify the problem and access step-by-step instructions on how to fix it, reducing downtime and minimizing the risk of human error. In a fast-paced environment where time is of the essence, this real-time troubleshooting capability is invaluable.

Interactive Training Simulations

Training new employees on how to operate and maintain complex electrical equipment can be a daunting task. Traditional methods of training, such as manuals or classroom sessions, can be time-consuming and ineffective. AR is changing the game by offering interactive training simulations that allow trainees to practice in a safe, virtual environment.

By using AR-enabled devices, trainees can simulate various scenarios and practice troubleshooting and maintenance tasks in a hands-on way. This not only accelerates the learning process but also improves retention rates, as trainees can apply their knowledge in a practical setting.

Remote Assistance

Another key advantage of AR in the maintenance of electrical equipment is remote assistance. With AR-enabled devices, technicians can connect with experts in real-time, regardless of their physical location. This means that if a technician encounters a problem they are unsure how to solve, they can quickly reach out to a more experienced colleague for guidance.

This remote assistance capability not only ensures that issues are resolved quickly and efficiently but also enables knowledge sharing among team members. By tapping into the expertise of others, technicians can enhance their skills and improve their overall performance.

Increased Safety

Safety is paramount when it comes to working with electrical equipment. AR is helping to improve safety standards by providing technicians with enhanced visibility and awareness of their surroundings. By overlaying digital information onto physical equipment, AR-enabled devices can highlight potential hazards and provide safety tips in real-time.

Additionally, AR can be used to create virtual barriers or warnings to prevent technicians from entering dangerous areas. This feature is especially useful in high-risk environments where the slightest mistake could lead to a catastrophic event.

Cost Savings

In addition to improving safety and efficiency, AR can also result in cost savings for companies in the electrical industry. By reducing downtime, minimizing errors, and streamlining training processes, AR can help companies save both time and money in the long run.

Furthermore, AR-enabled devices are becoming more affordable and accessible, making it easier for companies to implement this technology into their operations. With the potential for significant cost savings, it’s no wonder that many companies are turning to AR to enhance their training and maintenance practices.

The Future of AR in Electrical Equipment Maintenance

As technology continues to advance, the role of AR in the maintenance of electrical equipment will only become more significant. From real-time troubleshooting to interactive training simulations, AR is transforming the way we operate and maintain electrical systems.

By providing technicians with instant access to information, enhancing safety standards, and facilitating knowledge sharing, AR is revolutionizing the electrical industry. As more companies recognize the benefits of this technology, we can expect to see widespread adoption of AR in the coming years.

FAQs

What devices are compatible with AR technology?

AR technology can be used on a variety of devices, including smart glasses, smartphones, and tablets. These devices are equipped with sensors and cameras that enable them to overlay digital information onto physical objects.

How does AR improve training efficiency?

AR improves training efficiency by providing trainees with hands-on, interactive simulations that allow them to practice in a safe, virtual environment. By engaging trainees in practical tasks, AR accelerates the learning process and improves retention rates.

Is AR technology expensive to implement?

While AR technology was once considered prohibitively expensive, it has become more affordable and accessible in recent years. Companies of all sizes can now implement AR into their operations, resulting in cost savings and improved performance.

In conclusion, augmented reality is revolutionizing the way we train and maintain electrical equipment. From real-time troubleshooting to interactive training simulations, AR is enhancing safety, efficiency, and cost savings in the electrical industry. As technology continues to advance, we can expect to see even more innovative applications of AR in the maintenance of electrical equipment.