The Role of Collaborative Robots in Electrical Equipment Assembly and Testing

99 exch sign up, lotus 365.io, play exch.in:Collaborative robots, also known as cobots, have revolutionized the manufacturing industry in recent years. These robots work alongside human workers to improve efficiency, productivity, and safety on the assembly line. In the realm of electrical equipment assembly and testing, cobots play a crucial role in streamlining processes and ensuring high-quality products.

Increased Efficiency in Assembly Processes

Cobots are designed to perform repetitive tasks with precision and accuracy, making them an ideal solution for electrical equipment assembly. These robots can handle intricate tasks such as soldering, wire stripping, and component placement with ease. By integrating cobots into the assembly process, manufacturers can significantly reduce assembly time and improve overall efficiency.

One key advantage of using cobots in electrical equipment assembly is their ability to work non-stop without the need for breaks. This continuous operation ensures that production lines run smoothly and consistently, minimizing downtime and maximizing output. Additionally, cobots can be programmed to work at a faster pace than human workers, further enhancing productivity in the assembly process.

Improved Quality Control in Testing Procedures

In the testing phase of electrical equipment manufacturing, cobots play a crucial role in ensuring that products meet quality standards. These robots can be equipped with sensors and cameras to perform thorough inspections and detect any defects or malfunctions in the products. By using cobots for testing procedures, manufacturers can enhance the accuracy and reliability of quality control processes.

Cobots can also be programmed to conduct various types of tests, such as functional testing, electrical testing, and performance testing. These robots can perform tests quickly and efficiently, providing manufacturers with valuable data on product performance and quality. By leveraging cobots for testing procedures, manufacturers can identify any issues early on in the production process and take corrective actions to prevent defects and ensure product quality.

Enhanced Safety on the Assembly Line

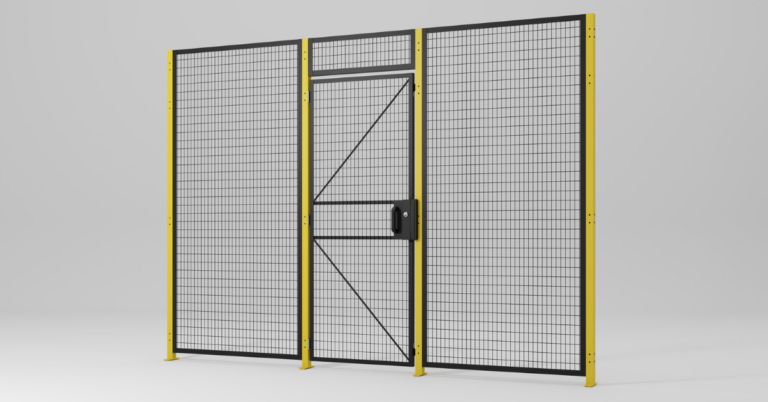

Another key benefit of using cobots in electrical equipment assembly and testing is improved safety for human workers. Cobots are equipped with advanced safety features, such as sensors and protective barriers, to prevent accidents and mitigate risks in the workplace. By working alongside cobots, human workers can avoid hazardous tasks and focus on more complex and strategic activities.

Cobots are designed to stop immediately when they encounter obstacles or unexpected events, ensuring the safety of both the robots and human workers. By implementing cobots in the assembly line, manufacturers can create a safer and more ergonomic work environment for their employees. This emphasis on safety not only protects workers from injury but also enhances overall productivity and efficiency in the manufacturing process.

Integration of AI and Machine Learning Technologies

In recent years, cobots have evolved to incorporate artificial intelligence (AI) and machine learning technologies, further enhancing their capabilities in electrical equipment assembly and testing. These advanced technologies enable cobots to learn from experience, adapt to changing environments, and improve their performance over time.

By leveraging AI and machine learning, cobots can optimize their movements, refine their tasks, and identify patterns in data to make informed decisions. These capabilities enable cobots to handle complex assembly processes and testing procedures with a high degree of accuracy and efficiency. The integration of AI and machine learning technologies into cobots represents a significant advancement in the field of manufacturing automation, revolutionizing the way electrical equipment is assembled and tested.

Future Outlook for Collaborative Robots in Electrical Equipment Manufacturing

As the demand for high-quality electrical equipment continues to grow, the role of collaborative robots in assembly and testing processes will become increasingly important. Cobots offer manufacturers a flexible, cost-effective, and efficient solution to meet production requirements and ensure product quality. With advancements in technology and automation, cobots will continue to play a pivotal role in shaping the future of electrical equipment manufacturing.

FAQs

1. What is a collaborative robot?

A collaborative robot, or cobot, is a type of robot designed to work alongside human workers in a shared workspace. These robots are equipped with advanced sensors and safety features to ensure safe and efficient collaboration with humans.

2. How are cobots used in electrical equipment assembly?

Cobots are used in electrical equipment assembly to perform tasks such as soldering, wire stripping, and component placement. These robots improve efficiency, productivity, and safety on the assembly line.

3. What are the benefits of using cobots in testing procedures?

Cobots enhance quality control in testing procedures by performing thorough inspections and detecting defects in products. These robots can conduct various tests quickly and accurately, providing manufacturers with valuable data on product quality.

4. How do cobots improve safety on the assembly line?

Cobots are equipped with sensors and safety features to prevent accidents and mitigate risks in the workplace. By working alongside cobots, human workers can avoid hazardous tasks and focus on more strategic activities, creating a safer work environment.

5. How do cobots integrate AI and machine learning technologies?

Cobots incorporate AI and machine learning technologies to optimize their movements, refine their tasks, and improve their performance over time. These advanced technologies enable cobots to handle complex assembly processes and testing procedures with a high degree of accuracy and efficiency.

In conclusion, collaborative robots play a crucial role in electrical equipment assembly and testing, helping manufacturers improve efficiency, productivity, and safety in the manufacturing process. With advancements in technology and automation, cobots will continue to drive innovation and transformation in the field of electrical equipment manufacturing.